Choosing the right vape manufacturer is the single most critical decision for any brand entering the e-cigarette market. A truly reliable vape factory goes beyond mere production; it acts as a strategic partner. This guide outlines a four-pillar approach to ensure you select a partner that guarantees quality, compliance, and long-term stability.

Pillar 1: R&D and Innovation Capability (The Future-Proof Test)

In the fast-evolving vaping industry, a manufacturer's R&D strength is paramount. Look for evidence of continuous innovation, which is a key indicator of a top-tier vape factory.

Key R&D Indicators:

Patented Technology: Does the manufacturer hold patents for core components like ceramic coils, leak-proof structures, or smart chip technology? This demonstrates genuine innovation, not just imitation.

Dedicated R&D Team: A significant investment in a dedicated R&D center and experienced engineers is crucial for developing next-generation products, such as advanced disposable vape manufacturer designs or new pod systems.

Prototyping Speed: The ability to quickly turn a concept into a functional prototype is vital for market responsiveness.

Pillar 2: Quality Control and Production Qualifications (The Reliability Test)

Quality is non-negotiable, especially when dealing with consumer electronics and e-liquids. A reliable vape manufacturer must demonstrate rigorous quality control at every stage.

| Evaluation Area | Key Indicators |

|---|---|

| Certifications & Standards | ISO 9001 (Quality Management), GMP (Good Manufacturing Practice), and specific regional certifications. |

| QC Process Implementation | Strict implementation of IQC (Incoming Quality Control), PQC (Process Quality Control), and FQC (Final Quality Control) systems. |

| Supply Chain Transparency | Clear sourcing of raw materials, especially A-grade batteries and USP/EP-grade e-liquid ingredients. |

For more details on quality standards, you can refer to industry best practices here. Always verify the validity of all claimed certifications.

Pillar 3: Compliance and Global Market Experience (The Risk Mitigation Test )

Navigating global regulations (like TPD in the EU and FDA in the US) is complex. Your vape manufacturer must be a compliance expert to mitigate legal risks for your brand.

Compliance Checklist:

TPD and PMTA Experience: Ask for their track record in assisting clients with TPD registration and FDA PMTA submissions. This is particularly important for any private label vape project.

Regional Expertise: A manufacturer with experience in key markets (e.g., Europe, North America, Southeast Asia) understands the nuances of local regulations and packaging requirements.

Documentation: They should readily provide all necessary safety data sheets (MSDS) and technical files.

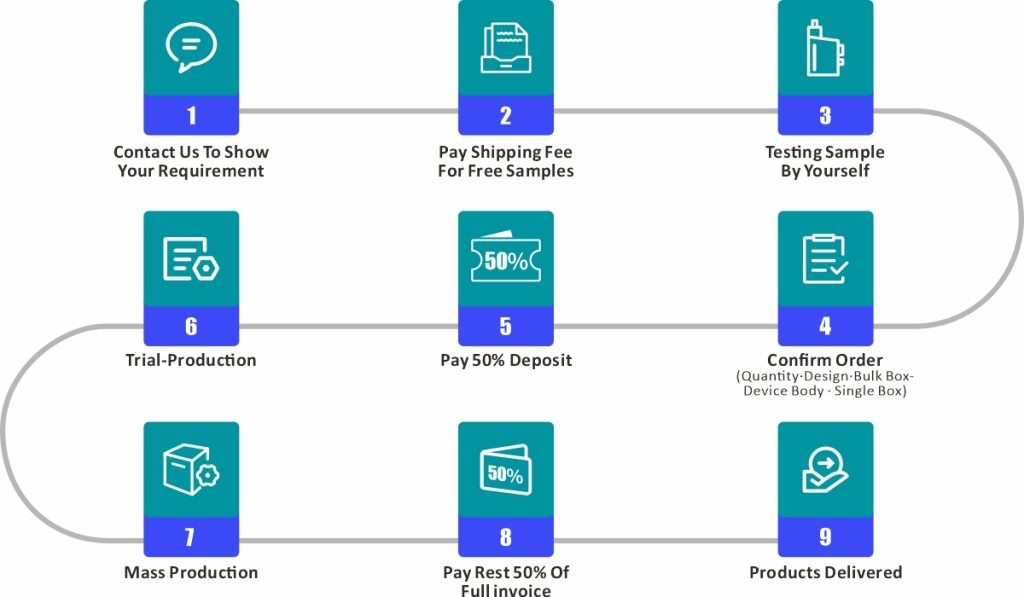

Pillar 4: Service Model and Commercial Flexibility (The Partnership Test)

Whether you require vape OEM or vape ODM services, the manufacturer's flexibility and support structure define the partnership.

Partnership Essentials:

OEM vs. ODM Clarity: A good partner clearly defines the scope of their vape OEM (production based on your design) and vape ODM (production based on their design) offerings.

MOQ and Pricing: While competitive vape factory price is important, focus on the total value proposition. A flexible Minimum Order Quantity (MOQ) can be a significant advantage for new brands.

After-Sales Support: A commitment to handling defects and providing technical support post-delivery is a hallmark of a truly reliable vape factory.

By applying these four pillars, you can confidently select a **vape manufacturer** that will be a cornerstone of your brand's success. For a direct consultation on your next project, please Contact Our Experts Today.